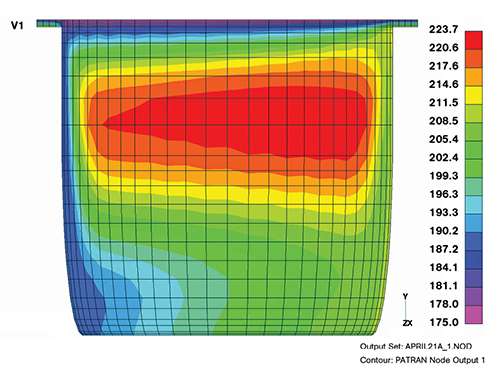

extrusion temperature profile

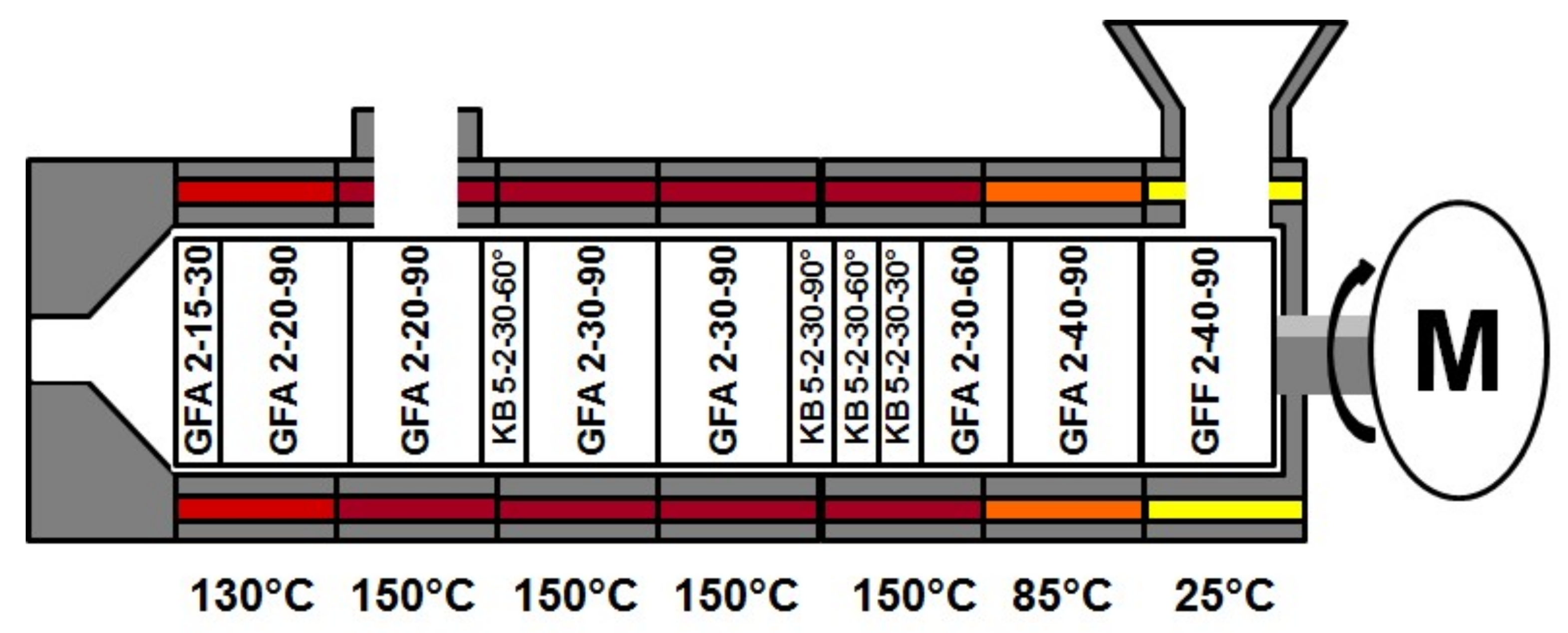

These temperatures are optimized for use with both kinds of plastic but PLA can often extrude at much lower temperatures. Temperature profiles vary greatly and include.

Barrel Temperature Profiles In C Download Scientific Diagram

Wait until the temperature stabilizes and extract the thermocouple by 2 in.

. Accurate across ALL relevant temperature ranges. At present three types of profile dies are used. Disconnect or shut-off auxiliary feeding and downstream equipment and thoroughly clean material feed system ensuring all components including blenders hoppers.

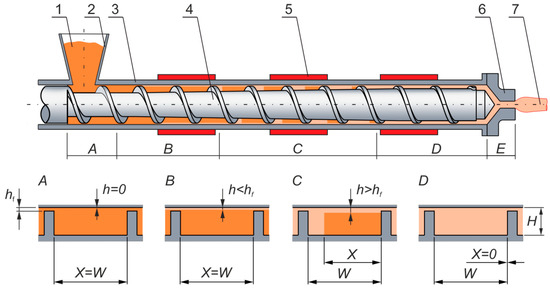

In our 5th generation and later printers we found PLA to work best at 215C at speeds of about 90 mms. Most extruders are single screw machines. Extrusion temperature profile Source publication 15 Development of nanofibrillar morphologies in poly L-lactidepoly amide blends.

Multi-wavelength with Static ESP Technology. All thermal performance data for one inch of extrusion All data is for Tambient 25C and P 10W MPN L mm W mm H of mmFins R 200 lfm oCW R 400 lfm oCW R 600 lfm CW R 800 lfm oCW R natural convection oCW R 200 lfm oCW Ducted ATS-EXL71-300-R0300 37 8 15 95 52 41 35 364 4 ATS-EXL71-1220-R01220. Three-zone screw 25 - 30 LD or barrier screw Compression Ratio.

Basically the orifice die consists of a die base and a die plate in which the profile is formed. They can also be co-extruded with other materials to yield a part with both rigid and soft components. This heat softening is called by various names such as plastication plasticization or thermal softening.

4 Friction extrusion edit Main article. If the molten plastic does not have the desired properties when it reaches the die head you will often have a difficult time achieving. If the rate seems too low try raising the set points on zones 2 and 3 above the set points of the other zones to form a hump in the profile.

Profile extrusion refers to the extrusion of polymer melts through dies of cross sections that are neither round annular or rectangular with an aspect ratio WH greater than 100. Orifice dies multistage dies and tapered profile dies. The die temperature will also influence output and will have an effect on the dimensions of the extrudate.

Please consult your material and. We use a temperature of 220C for ABS and PLA at speeds of 40 mms and lower and 230C at speeds up to about 100 mms. Accurate for temperatures below 900F500C.

Warm extrusion is done above room temperature but below the recrystallization temperature of the material the temperatures ranges from 800 to 1800 F 424 to 975 C. A Du Pont nylon extrusion study noted that exit-melt-pressure fluctuations were seven times more extreme after the temperature of the two rear zones was dropped 50 deg F. A Mobay processing handbook indicates that a 10-deg-F change in a 390F rear barrel zone can affect screw power by as much as 20 percent in extrusion of Texin 355D polyurethane.

Repeat this until the. Working with protective equipment insert the longest thermocouple into the nozzle tip as far as it will go. Our TPE compounds are easily extruded into single and complex profiles.

Barrier Screw 25 - 30 LD Compression Ratio. If the temperatures on the first few zones are set too low you will sometimes see small gels or unmelted particles in the extrudate. This will often improve feeding and therefore the rate.

Maintain temperature and RPM settings for resident resin. PP - Polypropylene Extruder. A cold die will restrict flow where as a too-hot die will affect dimensions.

In extrusion of a thermoplastic heating first softens the material so that it can be shaped. Assumes reasonably predictable surface character conditions. PC - Polycarbonate Extruder.

It is usually used to achieve the proper balance of required forces ductility and final extrusion properties. Single screw profile sheet film without vacuum plain feeding section with vacuum or pressure-relieved grooved feeding section by increased screw pitch and channel depth Screw Design. It is the screw.

200-250C 392-482F Melt Temperature. They exhibit improved profile flexibility. The SEBS compounds with their saturated intermediate blocks are very stable against thermal degradation.

The extrusion machine or extruder does this process. 50 mm and take another reading. Although peek is a super heat-resistant resin it has the characteristics of high temperature 350-400c good fluidity and high thermal decomposition temperature 560c so it can be processed by extrusion moldingpolyetheretherketone peek can be extruded through continuous extrusion to extrude peek rod peek film peek sheet peek pipe and.

Then set the temperature at the target purge a couple of shots build a shot and back the injection unit as far as it will go. Single Screw with vacuum grooved feeding section Screw Design. Role of the matrix elasticity and identification of the.

This is meant as a general guide. When optimum temperatures are reached it is known as the temperature profile. Proper temperature and heating control of the plastic inside of the extrusion barrel is very important to achieving high quality output whether you are a profile extruder wire coating sheet extruder or any other of the downstream processes.

The following are suggested purging procedures for extrusion profile as it applies to shutdown and startup.

Optimize Barrel Temperatures For Barrier Screws Plastics Technology

The Role Of Screw Design In Efficient Extrusion Of Medical Devices Plastics Technology

Example Of A Temperature Profile Of Plastic Extrusion Download Scientific Diagram

Extruder Barrel Temperature Settings Download Table

Initial Extrusion Conditions For The Pp And Hdpe Resins Used In This Download Scientific Diagram

Schematic Illustration Of The Extrusion Line And The Temperature Of The Download Scientific Diagram

Why Barrel Temperatures Have A Small Effect On Melt Temperature Plastics Technology

Understanding Viscosity In Extrusion Plastics Technology

Polymers Free Full Text Fundamentals Of Global Modeling For Polymer Extrusion Html

Pharmaceutics Free Full Text Inline Determination Of Residence Time Distribution In Hot Melt Extrusion Html

Example Of A Temperature Profile Of Plastic Extrusion Download Scientific Diagram

Barrel Temperature An Overview Sciencedirect Topics

Extrusion Results For The Pp Resin Download Scientific Diagram

0 Response to "extrusion temperature profile"

Post a Comment